MIL-DTL-82068D

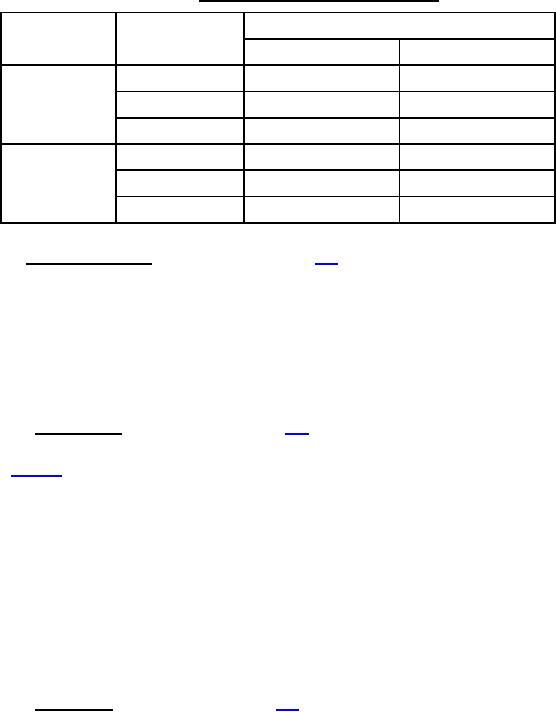

TABLE II. Flow control disk discharge rates.

Discharge in gpm

Flow control

disk size

Flow rate

Minimum

Maximum

A and B

Minimum

3

5

Intermediate

10

15

Maximum

20

25

C

Minimum

1

3

Intermediate

4

7

Maximum

8

11

3.7.9 Refiller assembly. When specified (see 6.2), the refiller assembly shall consist of a

venturi-type mixer discharge nozzle incorporating a clip or hook designed to hold the nozzle in

position for continuous discharge into the tank opening, a suitable length of high pressure supply

hose fitting with a quick-disconnect fitting for the pesticide supply connection on the sprayer,

and a suction hose assembly not less than 15 feet long fitted with a deep well-type intake strainer.

The refiller assembly shall deliver into the sprayer tank not less than 80 percent of the pump's

rated capacity, from a source of pesticide or water, at a lift of not less than 10 feet.

3.7.10 Spray boom. When specified (see 6.2), a spray boom, complete with all parts,

supports, and guides as necessary for mounting and operation when attached to the mounting

device (see 3.7.1.4) on the trailer, shall be furnished. The spray boom shall be constructed in

three sections, with adjustable supports to maintain the free ends in the desired positions during

spraying. Provision shall be made to automatically return the free ends to the desired spraying

position should they be deflected when encountering obstacles while traveling in either direction.

The overall length shall be not less than 20 feet, with not less than thirteen nozzles evenly spaced

along the boom. The spray nozzles shall have a brass body with a hardened stainless steel tip

equipped with a stainless steel nozzle, and shall produce a flat, fan-shaped spray in a 65-degree

angle at the tip. The discharge from each nozzle shall be approximately 0.67 gpm when supplied

with pesticide at 50 psi. Each section of piping shall be provided with not less than one clean-out

and drain plug. Nozzles shall be threaded or shall be provided with a leak-proof connector.

3.7.11 Service kit. When specified (see 6.2), a service kit shall be provided with each

sprayer. The service kit shall contain adequate parts for two complete changes of all field-

replaceable non-metallic seals. As a minimum, the service kit shall provide parts to replace the

following:

a.

Pump piston seals.

b.

Pump check valve disks.

c.

Pressure regulator seals.

d.

Agitator shaft packing.

e.

Cover gaskets.

f.

V-belts.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business